Sheet metal processing 1

Laser cutting technology allows us to produce processed parts at the fastest and best cost, while maintaining the highest quality standards.

Sheet metal manufacturing is the process of turning flat metal plates into parts and structures of various shapes.

Customized sheet metal brake (forming/bending) service laser cutting parts, providing precise bending results plus superior repeatability.

Sheet metal processing is the process of processing a piece of metal into a desired shape by bending, stretching, and removing material.

The bending process results in a v-shaped, u-shaped, or channel-shaped shaft, creating a new part geometry.

The typical sheet metal parts we produce include enclosures, brackets, components, weldments, cabinets and other parts.

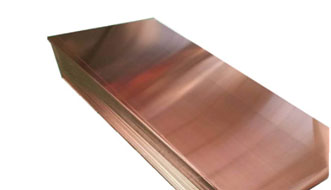

Metallic material

Below is a list of metals that our standards can be used for CNC machining. If you need customized information, please contact us

Aluminum

Stainless steel

Brass

Copper

Alloy steel

Bronze

Titanium

Carbon steel