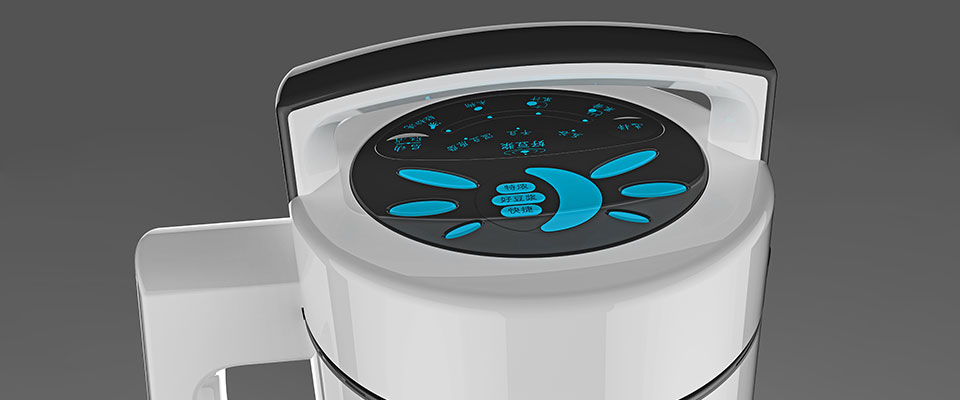

Home appliances

Appearance Prototype

Through appearance

prototyping, manufacturers are able to create a model that meets the aesthetic

requirements of the customer in terms of material, color, etc. of a given home

appliance.

This allows them to

evaluate the effectiveness of the design and surface color treatment prior to

production.

Home appliances

Functional Prototype

Honpe's electronic engineers have enabled us to combine the

electronic design with the physical model to simulate the product's

functionality, providing a functional prototype.