The development status of my country's profile mold industry

2021.10.16

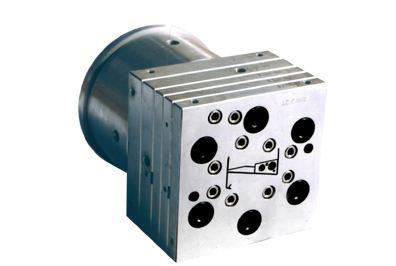

The development of my country's profile mold industry has received increasing attention and attention. In products such as electronics, automobiles, motors, electrical appliances, instruments, meters, home appliances, and communications, 60% to 80% of the parts must rely on profile mold forming. It is understood that in recent years, with the accelerated transfer of manufacturing production bases to China, the rapid upgrade of China's manufacturing industry has driven the accelerated development of the profile mold industry.

1. Analysis of the development status of the automotive profile mold industry. With the intensified global competition in the automotive market, in order to reduce the cost of new car development, foreign auto manufacturers have entered China to purchase automotive panel profile molds. Ford, Fiat, etc. have established China profile mold procurement In the center, GM has closed 4 out of 5 profile mold plants and switched to China for procurement. With years of cultivation in the domestic automobile market, a number of manufacturers have emerged that have the ability to undertake the production of automotive profile molds in the world. International automobile giants will increase their procurement efforts in China, which will rapidly increase the export volume of automotive panel profile molds in my country.

2. Analysis of the development status of the automation equipment parts industry. The manufacturing of automation equipment parts is an important supporting industry of automation equipment, which is widely used in automobiles, CNC machine tools, automated conveying equipment, robots, transformer manufacturing and other fields. The characteristics of high quality, high precision, easy operation and easy management of automation equipment in the production of enterprises in various industries have made it an indispensable mechanical equipment in the production process of enterprises, and have driven the increase in the demand for automation equipment parts. At the same time, the requirements for the specialization of structure and shape, the diversification of parts and materials, and the high precision of size and surface quality of automation equipment parts are also getting higher and higher. The general machinery parts industry, where automation equipment parts are located, has maintained a growth rate of more than 20% for many years. It has formed a comprehensive, large-scale and competitive industrial system and has become an important basic industry of the national economy. At present, my country's general machinery parts industry has annual sales of more than 250 billion yuan and exports more than 7 billion U.S. dollars. my country has become a major country in basic parts manufacturing.

Although my country’s profile mold production volume currently ranks third in the world, the overall design and manufacturing level lags behind Germany, the United States and other countries. Moreover, in the international market competition, my country’s profile mold industry lacks independent brands and leads to overall competition. The lack of strength is very unfavorable to the development of my country's profile mold companies in the global economic market. Industry insiders pointed out that improving the competitiveness of my country's profile mold manufacturing enterprises and building an independent brand in my country's profile mold industry have become the main problems facing the profile mold industry. According to incomplete statistics, there are currently more than 2,000 mechanical hardware profile mold sales and service agencies in Guangdong Province, but only two or three companies have their own brands. Industry insiders pointed out that due to the lack of its own brand, the average annual output value of profile molds created by each employee in China is about 10,000 US dollars per year, while most of the profile mold industry in developed countries is 150,000 to 200,000 US dollars, and some even reach 250,000. 300,000 US dollars. Generally speaking, most of the domestic profile mold manufacturing companies have weak development capabilities and no brands, resulting in poor economic benefits and often in a passive position in the market. In order to enhance its competitive strength and build its own brand, the profile mold industry is constantly improving the technical level of the industry, while making full use of the advantages of the mobile Internet to create a good corporate brand image, so as to achieve the goal of enhancing the soft power of corporate competition.